Wire ropes are essential components in many industries, from construction and mining to shipping and manufacturing. Among the most versatile types are the 6x19 and 6x36 class wire ropes. But how do you know which one suits your needs best? In this article, I will guide you through the key differences, applications, and selection tips to help you make an informed decision.

Have you ever wondered what 6x19 or 6x36 really means when it comes to wire ropes?

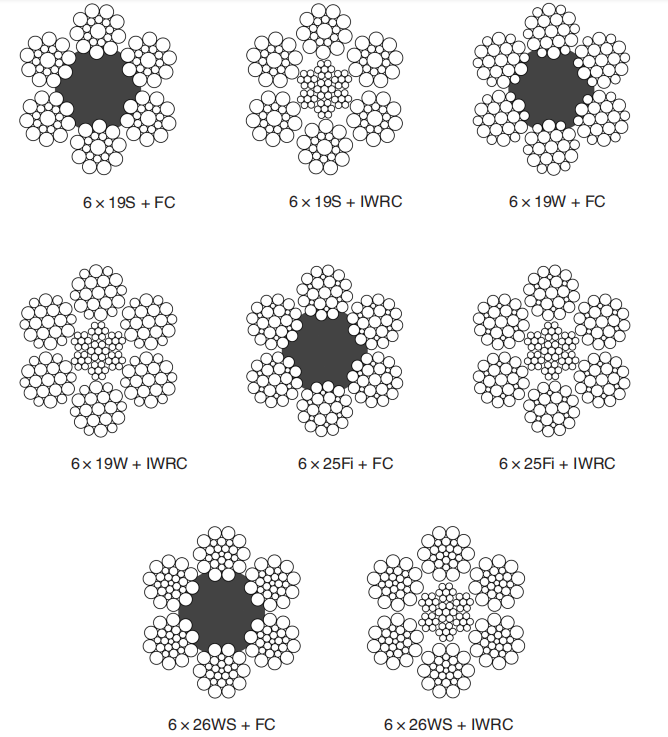

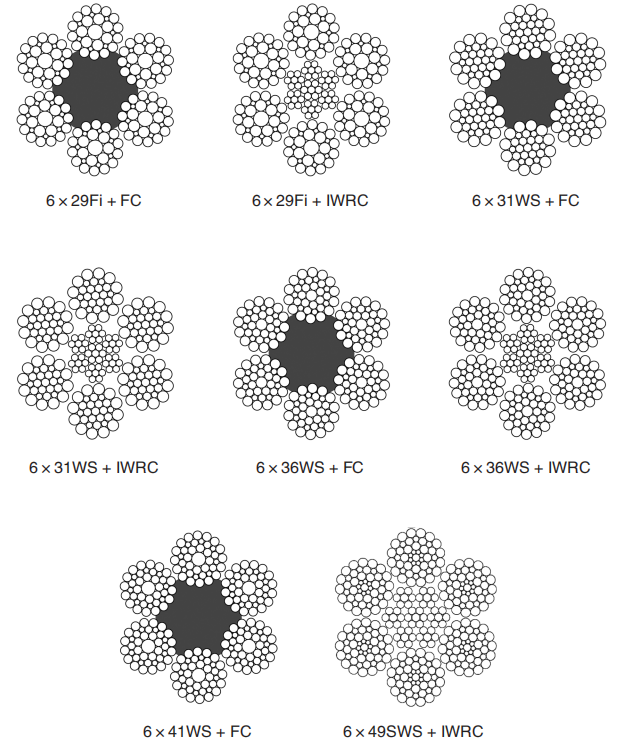

The numbers describe the rope construction:

6x19: 6 strands, each containing 19 individual wires

6x36: 6 strands, each containing 36 individual wires

The first number is the number of strands, and the second number is the number of wires per strand.

Both 6x19 and 6x36 fall under the general-purpose wire rope category, which means they can handle a variety of lifting, hoisting, and rigging tasks with reliable performance.

6x19: Medium flexibility. It is stiffer due to fewer, larger wires.

6x36: High flexibility. More wires per strand make it easier to bend around sheaves and pulleys.

6x19: Larger wires offer better abrasion resistance, making it ideal for rugged lifting environments.

6x36: Smaller wires give it higher flexibility but slightly less resistance to wear.

6x36: Excellent for repeated bending, such as ropes in hoists and luffing cranes.

6x19: Slightly less fatigue-resistant but suitable for direct load-bearing applications.

IWRC (Independent Wire Rope Core): Strong core for heavy-duty hoisting.

WSC (Wire Strand Core): Slightly more flexible but lower strength than IWRC.

Fiber Core (FC): Cushions the strands, offers more flexibility, but less abrasion resistance.

For 6x36, the flexibility advantage is often enhanced with IWRC cores for heavy-duty bending applications.

| Wire Rope | Common Uses |

| 6x19 | Cranes, winches, hoists, general lifting, rigging |

| 6x36 | Luffing cranes, elevators, mining hoists, bending-intensive applications |

These ropes are widely used in construction, shipping, mining, manufacturing, and offshore operations.

Here are some key questions to ask before making a choice:

Do you need high abrasion resistance or high flexibility?

Abrasion → 6x19

Flexibility → 6x36

Will the rope bend over small sheaves frequently?

Frequent bending → 6x36

Rare bending → 6x19

What is the load capacity required?

Check the minimum breaking force (MBF) for your rope diameter.

What type of core is needed?

Heavy loads → IWRC

Light duty and flexibility → FC

Proper maintenance ensures long rope life and safety:

Lubrication: Reduces wear and prevents corrosion.

Inspection: Regularly check for broken wires, corrosion, or strand distortion.

Replacement: Follow industry standards for number of broken wires or visible damage.

| Feature | 6x19 | 6x36 |

| Flexibility | Medium | High |

| Abrasion resistance | High | Medium |

| Fatigue resistance | Medium | High |

| Core types | IWRC/WSC | IWRC/WSC |

| Applications | General hoisting | Hoisting with sheaves, bending-intensive |

At Aulone, we focus on premium quality wire ropes that combine strength, flexibility, and durability. All our wire ropes are:

Customizable to your specifications

Certified and tested by third-party inspection agencies

Backed by expert technical support

Whether you need 6x19 for heavy lifting or 6x36 for bending-intensive applications, Aulone provides reliable solutions tailored to your industry needs.

Website: www.aulone.com

Email: info@aulone.com

Contact: AULONE

Phone: 86-15573139663

Tel: 86-15573139663

Email: admin@aulone.com

Add: Address:Kaiyuan road 36,Chunkou,Liuyang, Hunan,China. Email: info@aulone.com