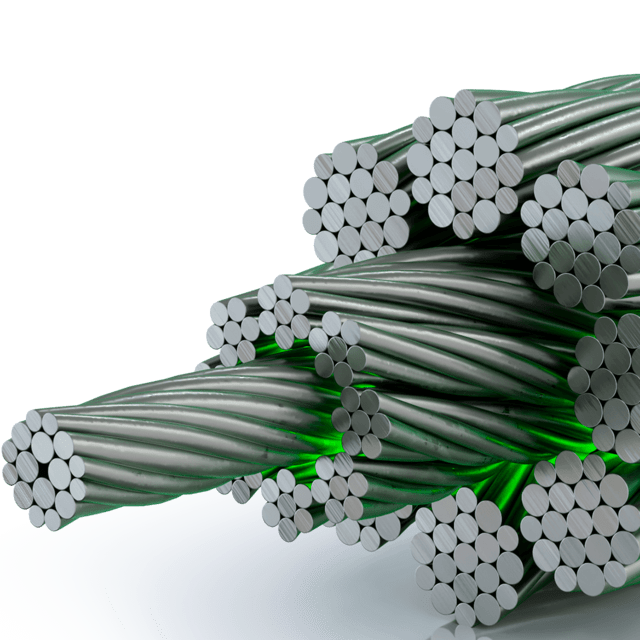

Common quality problems and inspection methods of elevator steel wire rope

[Abstract] The wire rope is one of the important components that play the role of elevator load and traction car in the elevator traction system. This article introduces that common quality issues & inspection method of steel wire ropes, Guiding the operator to quickly discover the quality defects of the wire rope, formulate countermeasures in time to ensure the safe operation of the elevator.

Keywords: Steel wire rope inspection, the quality of the wire rope; broken wire, broken strand.

As a direct component of elevator steel wire as an elevator load and traction car, the quality and performance of the elevator directly determine the comfort and safety of the elevator operation. In the process of installation and use of elevators, due to many complex external factors, the wire rope often has different degrees of quality problems. Therefore, in the process of installation, maintenance and use of elevators, special attention should be paid to the quality inspection of elevator steel wire rope. The following will introduce the adverse problems of the wire rope and summarize the relevant inspection methods to help operators quickly find out the poor quality points and reasons for the wire rope, and take response measures in time.

Traction steel wire ropes common issues introduction

The common adverseness of elevator steel wire ropes is simply divided into two types: "trauma" and "internal injury". The main manifestations of trauma are: deformation, wear, damage, bending, twisting, large twisted splittering, large gaps in the stock, exposed rope core, rust, oil deficiency, obvious filament, broken stocks, etc. The main manifestations of internal injuries are: Stress accumulation, uneven tension, uneven diameter, rope core break, steel wire dullness, etc. Although some of the above -mentioned appearances are similar, the reasons for forming may be different, or they are caused by multiple factors. The phenomenon of poor wire rope on the spot is:

1. During the molding process of steel wire rope twisting stocks, the gap between the rope stocks caused by the machine failure or operating error, the rope core is exposed, the twist distance, and the cage -shaped deformation.

2. During the storage and transportation process, due to the damage or protection of the packaging, the wire rope was exposed to the sun, causing the oil and rust oil to exudes, or it was rusted due to rain, water soaking, and moisture.

3. Simple packaging steel wire rope (simple circle into a plate shape) is too long, the wire rope will be flattened and deformed, and the wire rope will be bent after the installation

4. During the installation process, abnormal damage and bend caused by the scraping of hard objects such as slot steel, brick wall, sand and stone.

5. No protection is taken during welding or cutting operations, causing the wire rope to be burned by welding slag and cut by the cutting machine.

6. The front steel rope is not fully released by the front stress (that is, "deflection"). The two rope head ends are fixed. Or the "deflation" suspension time is too long, the wire rope becomes loose under the action of gravity, the gap between the stocks becomes larger, and even causes the rope core to break the steel wire first.

7. When the wire rope is installed, the rope is not used when the turntable or the drum is not used in the wrapping direction when the wire rope is packed, or the wire rope is forcibly pulled out of the inner ring, causing the wire rope to "accumulate" and twist.

8. The installation and maintenance process was not adjusted in time, and the tension value between the steel wires was too large, resulting in unevenness of the wire rope, the abnormal wear of the steel wire rope inconsistent diameter or the rope rope groove was not consistent.

9. The steel wire rope lacks maintenance and does not take timely and rust removal. The cause of the steel wire rope is dry and lacks of oil and rusted "red powder".

It can be seen that there are many factors that affect the quality of the wire rope at the complex engineering site. In addition to the operation and transportation process, the operators must pay attention to the installation and adjustment in the process of installation and maintenance. In addition to the "internal injury", inspectors must also strictly check the quality of the wire rope. It is necessary to take countermeasures in time to find that poor steel wire ropes are used to prevent flowing into the elevator installation and use.

Common inspection method for elevator electrical wire rope

It can be known from the steel wire rope introduced above, Some bad eyes can be found through the appearance of the steel wire rope through the naked eye, but some bad observations are difficult to distinguish through the surface observation, so it is necessary to use the amount of ingredients and instruments for inspection. Some bad are not manifested when the steel wire rope is installed, and it is only manifested after using the wear. Therefore, we must check the wire rope regularly according to the use of the elevator. The main inspection methods of some steel wire ropes are summarized below for operators for reference

For the inspection of the wire rope, we must first confirm that the installation meets the design requirements and process requirements. Usually confirming the type and diameter of the wire rope meet the design book requirements, whether the installation order of multiple steel wire ropes meets the requirements, whether the rope terminations meets the requirements (Including the reliability of accessories such as rope clips, nuts, nails and other accessories), the rope wheel wheel Whether the verticality of verticality, traction wheel and guide wheel meet the requirements, etc. If these projects do not meet the requirements, they will cause abnormal wear of the wire rope. For example: If the parallel degree of the traction wheel and the guide wheel exceeds the standard, it is easy to cause the steel wire to arrest partially. The U -shaped rope clip installation error causes the wire rope to clip, because the sliding saddle of the U -shaped rope is specially designed, which has anti -skids and protective steel wires. The role of the arrest, and the U -shaped bolt is not, so the sliding saddle must be installed on the side of the main rope of the stress, otherwise the U -shaped bolt will clip the wire rope.

Secondly, we need to regularly check and monitor projects that reflect the quality changes of steel wire rope, such as: diameter, twisting, tension, oil rust, broken wires, abnormal wear, abnormal deformation, rope wheel wear, etc. The principles of the total inspection of these projects can be included as: "See" Two "Touch" and Three "Test". "Look" is to observe the appearance of the steel wire rope with abnormal deformation, wear, bending, rusty shares, broken wires, uneven diameter, and rope core exposure. "Touch" is the surface with a glove to touch the steel wire or use a special scraping ruler light scraping wire rope to see if there is a broken steel wire hook the glove or scrape the scraper. "Testing" is one of the best ways to measure the diameter, twisting, and tension of the wire rope; and the use of the detector to explore the wire rope is one of the best ways to find the inner and outer wire of the wire rope and the damage of the stock.

The specific inspection and judgment method of diameter, twisting distance, tension, oil content, rust, rope wear, and rope wear are as follows.

1. Diameter check: The diameter of the outermost side of the rope stocks with a wide -cutting staller should be used to measure the diameter of each rope. The average value should be measured multiple times on the flat part of the wire rope. Compared with the diameter of the same position and other neighboring wire ropes. In the case of loading, the diameter deviation range is 0 ~ 0.5mm; if the diameter is worn to less than 90%of the original size, new rope needs to be replaced.

2. Wing distance check: The twist distance refers to the straight line distance between the rope stock rotation around the rope when the rope is rope. You can use a pencil to printed the contour of the steel wire rope on the white paper. According to the number of stocks of the wire rope, the distance between the corresponding stocks on the white paper is used to measure the distance from the white paper. As shown in the figure below (the schematic diagram of the 8 -stranded wire rope twisting distance). The twisted distance should not exceed 6.75 times that of the nominal diameter of the wire rope. If it exceeds the range, check whether the wire rope has excessive reverse rotation, the rope core break, and replace or adjust in time.

3. Steel wire rope tension check: For those with rope head springs, the height of the height is used to measure the height of the spring, and its height error should be less than 2mm. For the elevator without rope head, the elevator is parked at 2/3 height, on the roof of the sedan, and on the roof of the section On the above, the opposite side of the steel wire rope was pulled out of the same distance, and the tension between its phase and the tension must not exceed 5%; the required required should be adjusted in time.

4. Oil content check: Observe whether the surface of the rope groove and the surface of the wire rope is dry, no oil, and whether the oil on the edge of the rope groove is dry. Press the wire rope with your fingers (white cloth or white gloves) to observe whether the finger (white cloth or white gloves) is accompanied by oil traces. If there is no oil trace, it means that the wire rope oil is insufficient and the steel wire rope is required.

5 The rust of the wire rope inspection: Observe whether the wire rope is dry and rusty. If the wire rope has rust spots or rust between the stocks, the rust removal should be performed: such as the steel wire rope is fully rust or even dry powder or red powder is scattered, it should be replaced immediately.

6. Rope wheel wear inspection: Tighten the round surface along the axis of the axis, and then measure the top point of the wire rope in the tank until the distance of the ruler. When its deviation is 1.5mm, check whether the wire rope is slipped in the rope groove or check whether there are individual steel ropes abnormally worn.

The above we introduce the quality of the common steel rope and summarize the inspection methods of the main inspection items. I hope that it can help operators to quickly find the poor quality points and reasons for the wire rope, and take response measures in time. Steel rope is the most important safety component of the elevator. We must take protection measures and check and maintain regularly during installation or during use to ensure the quality of the wire rope, extend the service life, and ensure the safety of the elevator.

Contact: AULONE

Phone: 86-15573139663

Tel: 86-15573139663

Email: admin@aulone.com

Add: Address:Kaiyuan road 36,Chunkou,Liuyang, Hunan,China. Email: info@aulone.com