8X84WSNS-IWR一120mm high strength galvanized steel wire rope production

Abstract: in order to meet the ocean vessel for high strength, thick diameter galvanized steel wire rope, as Baosteel 77 hot rolled wire rod raw material, drawing using straight into type wire drawing machine, used hot galvanizing technology, Strictly control the spacing and bending capacity of the three rolls of the pre-and post-deformer during twisting,Diameter of wire rope is controlled by sizing device.

producing more than 120mm diameter wire composite structure 8x 84 WSNS+I WR galvanized steel wire rope,the minimum breaking tension of the wire rope produced is 8570kN.

1. Technical requirements of wire rope

The marine and fishing steel wire rope is a new variety of steel wire rope manufacturing industry in China. Because of the special conditions of this kind of wire rope,not nonly the performance requirements of the wire rope are very high,but also the diameter of the wire rope is large,Moreover, it has high requirements on the mechanical properties and anti-corrosion effects of steel wire ropes,the failure modes of marine and fishing ropes are mainly manifested in:

(3) Anti-corrosion grease can not meet the requirements, there is no grease between the wire rope surface and the inner layer steel wire, or the oil is not enough, causing early corrosion of the steel wire. In point contact, line contact, surface contact wire rope, point contact wire rope is not Wear resistance and fatigue resistance are poor; although the surface contact wire rope has the characteristics of high tensile strength and wear resistance, its hardness is also the highest, and the softness performance is the worst. Therefore, the surface contact wire rope is not in line with the selection of marine and fishing wire rope requirements. Wire contact wire ropes, especially multi-strand and multi-filament composite wire ropes, are widely used in marine fishing, ship traction, and marine lifting due to their structural characteristics.

2. Steel wire production process

2.1 Raw material selection

Due to the high tensile strength (1770 MPa) and high toughness of the galvanized steel wire rope produced in this production, in order to meet the technical requirements, the principle of wire rod selection is established:

(1) Increasing the carbon content of raw materials or alloying raw materials;

(2) increase the total compression ratio;

(3) Reduce the bath temperature. If the content of P and S in the raw material is too high, the brittleness of the steel wire will be improved, the toughness will be lowered, and the bending and torsion properties of the steel wire will be poor. The uneven metallographic structure and the low proportion of the sorbite will deteriorate the toughness of the raw material and reduce the shrinkage of the section. The surface of the steel wire is prone to form micro-cracks and even lead to broken wires. In order to improve the mechanical properties of the steel wire and control the uniformity of the steel strip, the wire rod with the carbon mass fraction of 0.75% to 0.78% is used. The Baosteel 77A hot rolled wire rod has good mechanical properties and processing properties. so as this raw materials for this production.

2. 2 steel wire production process

The choice of galvanizing process not only directly affects the mechanical properties of semi-finished ropes, but also has a decisive influence on the overall performance of the ropes. Therefore, when designing the galvanizing process, the focus is on the zinc pot temperature, zinc immersion time, zinc immersion length and zinc immersion,and the speed was designed. The galvanizing electromagnetic wiping technology plays a great role in the performance control of the steel wire in this production process. The mechanical properties of the galvanized steel wire after electromagnetic wiping completely meet the design requirements. In order to meet the performance requirements of the wire rope, Firstly, the heat treatment of the finished steel wire adopts the gas-heated steel tube muffle furnace, that is, the steel wire travels through the heat-resistant steel pipe, avoiding the quality problem caused by the decarburization of the steel wire surface; secondly, the tensile strength of the steel wire is improved by controlling the lead temperature; Third, according to the wire specifications and the characteristics of the wire drawing machine, the pickling thin phosphating coating drawing process is used to improve the surface quality of the finished steel wire and reduce the tendency of the wire to be brittle. The rope is made of the first plating and the pulling process. The raw material steel wire is selected by the 9/600 straight wire drawing machine for the first drawing. While the water cooling effect of the wire drawing machine is enhanced, the method of increasing the total compression ratio and the smaller partial compression rate is adopted. The tensile strength and toughness of the steel wire for galvanizing ropes are to ensure that the comprehensive mechanical tensile strength of the steel wire rope is not less than 1720 MPa, and the nominal tensile strength is 1770 MPa.

3. Wire rope production process

3.1 Structure of the strands in the wire rope

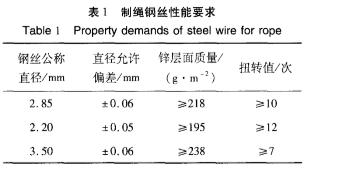

The wire rope is made of 8 X 84WSNS+I WR structure, and its strand structure is 1+7+7/7+1 4~24+24, see Table 1.

3.2 Distribution and tanning process parameters

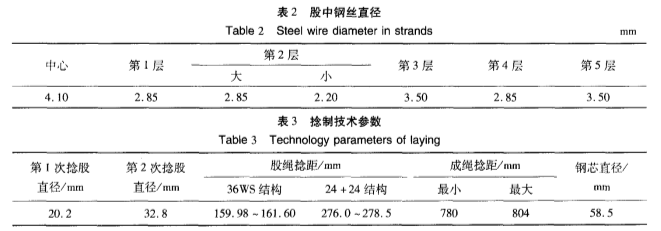

The nominal diameter of the wire rope is 120mm, and the stock is divided into 2 times. The diameter of the strand is calculated to be 32.8mm, thus determining the performance of the steel wire in the strand. The performance of galvanized steel wire are shown in Table 1. The diameter of the anti-diameter is shown in Table 2, and the parameters of the tanning are shown in Table 3.

3.3 Strand and rope restraint

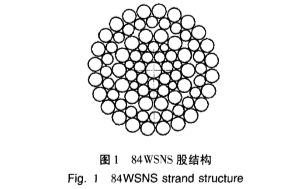

3. 3.1 8 X 84WSNS steel wire strand structure is 1+7+7/7+l 4-24+24, the inner part is the Wulinton-Silu composite structure, and the outer layer is surrounded by thicker steel wire to form the Xilu structure. While increasing the softness of the strand, it also improves the wear resistance of the strand.The shares are divided into two times. The inner and outer steel wires are not the same, and the design is based on the customer's requirements. The inner layer of the Wlinton-Silu composite structure has a distance of 160mm and the outer layer of the Silu structure. The distance is 275 mm, and the distance between the ropes is 780 mm. When selecting the stock, select 1 2/500+18/500+24/500 tandem machine for 2 times, and use 8/1 250 rope machine for tanning.Since the diameter of the wire rope exceeds the original design requirements of the rope making machine, the electrical and mechanical systems of the 8 / 1 250 rotary machine are thoroughly inspected before the rope is assembled.Some parts have been improved, and the multiples of the strands and ropes are smaller than the multiples of the ordinary steel wire ropes, in order to enhance the softness and wear resistance of the wire rope.The 8×84 WSNS structural steel wire rope produced this time has the characteristics of thick outer layer of Xilu wire rope, abrasion resistance, anti-extrusion and soft interior. It also has the characteristics of soft and anti-bending fatigue of Wallinn wire rope.

The structure of the 8×84 WSNS wire rope is the RHRL, the method of the wire rope is the right lay, and the method of the strand is the left ley. The rope core adopts 8×1 9 steel core structure to enhance the breaking tension of the steel wire rope, which not only meets the safety factor but also increases the service life.

3. 3.2 Using the twisting device

Wire rope performance can be improved by pre-deformation and post-deformation. In order to make the wire rope have good non-loose performance, the tanning stress should be eliminated. The following measures are taken in the production:

1) Straightener is added on the wire drawing machine of the wire drawing machine; (2) The deformer is arranged on the ramming machine; (3) The strand is pre-deformed when the rope is spliced on the rope forming machine, and then deformed after the rope is spliced;(4) Install the sizing device. Compressing and sizing the wire rope to improve the surface quality of the wire rope. After the straightening of the wire-drawn straightener, the deformation of the strand, the pre-deformation of the strand, the deformation of the wire rope, the sizing of the wire rope, etc., the tendon stress is eliminated, and the wire rope has good non-loose performance, compact structure, small ovality, uniform diameter, excellent fatigue resistance, long service life and significant improvement in physical quality.

3.3. 3 core and strand surface treatment

The structural characteristics of the steel wire rope, the quality of the steel wire and strand twist have a decisive influence on the use effect of the steel wire rope. The effect of the lubricating effect on the service life cannot be ignored. The use of the superior quality grease can not only meet the storage and transportation requirements of the wire rope, but also Effectively extend the life of the wire rope. The oil rope is subjected to a leaching process when the strands are twisted, and the surface is oiled when the ropes are spliced; in the process of tamping the cord core, the surface of the wick is oiled to ensure sufficient lubrication between the wires in the strands, thereby achieving enhance the corrosion resistance and lubrication performance of steel wire.

3.3. 4 strand length production

Although it is allowed to weld the steel wire in the strand, the mechanical properties of the welded wire are greatly different from those of the base. In particular, the wire rope produced this time has a large specification and the steel wire is thick, so the drawing of the finished steel wire is determined. ruler production (especially the outer wire of the strand) ensures the performance of the strands.

4. Wire rope performance analysis

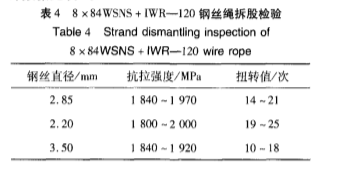

The mechanical properties of steel wire ropes are tested according to GB/T 20067-2006

The tensile strength test is carried out according to GB/T 228-2002 (Metal material tensile test method for room temperature); the torsion test is carried out according to GB/T 2 3 9 - 1 999 (Metal wire torsion test method) Both the diameter and the tensile strength meet the requirements, and the minimum breaking force of the wire rope reaches 8 570 kN. The statistical data of the wire rope splits developed is shown in Table 4.

5 .Conclusion

The development trend of marine and fishing wire ropes should be based on multi-strand, multi-wire composite wire contact wire ropes. The multi-strand, multi-filament composite wire contact wire rope has a large filling factor, a large number of steel wires, a relatively small size, a large number of strands in the steel wire rope, and high toughness, so the wire rope has good flexibility and is advantageous for improving the service life of the wire rope. In the production process, the galvanized electromagnetic wiping technology is adopted, the sputum leaching oil and the surface treatment of the core are used, and the pre- and post-deformers are used to eliminate the stress in the process of tying the rope. At the same time, the use of the sizing device is combined to greatly improve the overall quality of the steel wire rope. .The 8×8 4WSNS+I WR-120mm, 1770 MPa high-strength coarse-diameter multi-wire composite structure galvanized steel wire rope has a good reputation all over the world.

Contact: AULONE

Phone: 86-15573139663

Tel: 86-15573139663

Email: admin@aulone.com

Add: Address:Kaiyuan road 36,Chunkou,Liuyang, Hunan,China. Email: info@aulone.com