Aulone’s Locked Coil Ropes are reknown for their strength, rotation resistance and reduced stretch. They can be fully customized to suit every client’s need and requirement, including layers of “Z” shaped wires. In order to do so, Aulone has developed a specialized design through its advanced software which, in addition to the company’s total control of the manufacturing process, guarantees the best performance in any application such as track ropes for bicable aerial cableways, Koepe hoists etc.

TECHNICAL FEATURES

Locked coil rope

Steel core

Regular Lay

Wire coating: Zinc or Zn95Al5

Reference standards: EN 123854, EN 12385-9

Locked coil steel wire ropes are a kind of special single-twist steel wire rope with compact structure, smooth surface and good sealing performance. It is made of ordinary single-twist round strand steel wire rope as the core and is wrapped with one or more layers of special-shaped steel wire. . The diameter is 20 ~ 70mm, according to the surface condition of the steel wire, including phosphate coating Locked coil steel wire ropes, galvanized Locked coil steel wire ropes and smooth Locked coil steel wire ropes.

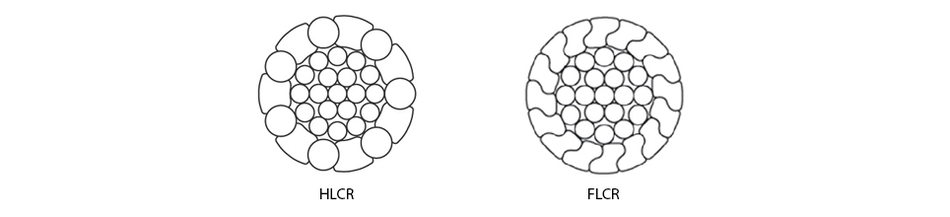

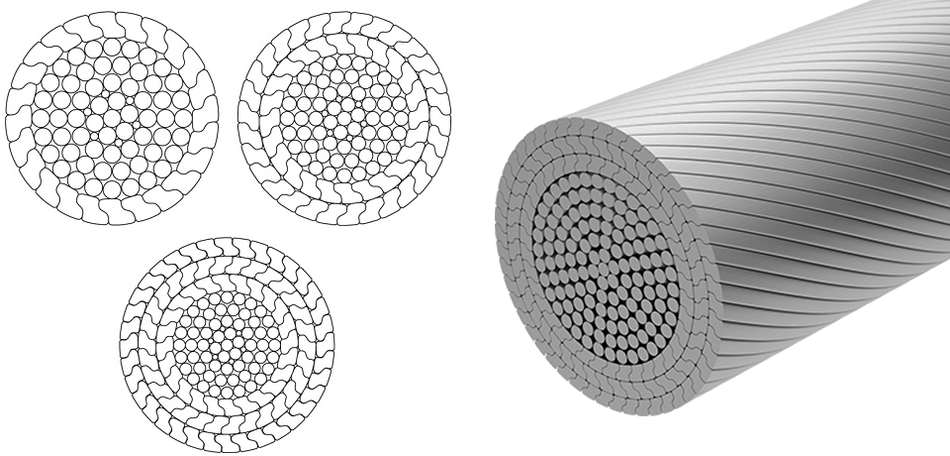

Structure

The locked coil steel wire ropes has a compact structure, a smooth surface, non-notation, good sealing, but poor flexibility. According to the degree of sealing, there are full-locked coil steel wire ropes and half-locked coil steel wire ropes. According to the surface condition of the steel wire, there are two kinds of galvanized and smooth locked coil steel wire ropes.The structure of the locked coil steel wire ropes depends on the shape and composition of the outer steel wire.

The outer layer steel wire has the following forms:

(1) one layer of Z-shaped wire (figure a);

(2) two layers of Z-shaped wire;

(3) one layer of Z-shaped wire and one layer of trapezoidal wire (figure b);

(4) two layers of Z-shaped wire Steel wire and one layer of trapezoidal wire (figure c);

(5)one layer of Z-shaped wire and two layers of trapezoidal wire (figure d);

(6)two layers of trapezoidal wire and one layer of Z-shaped wire in sequence;

(7)Herringbone wire (figure) ); or round and rail-shaped (X-shaped) steel wire twisted structure (figure f), the steel wire rope of this structure is a semi-sealed steel wire rope; if another layer of Z-shaped steel wire is added to the outer layer, a locked coil steel wire ropes is formed (Figure g);

(8) consists of one layer of Z-shaped steel wire and one layer, two layers (figure h) or three layers of rail wire and round steel wire in turn.

Characteristic

Compared with ordinary steel wire rope, the performance characteristics of locked coil steel wire ropes are:

(1) The density coefficient is large, up to 0.9 or more, which is the crown of various steel wire ropes; compared with ordinary steel wire ropes of the same diameter, the total breaking tension is about 65% higher.

(2) The whole wire rope is similar to a round bar, with a large supporting surface, less pressure per unit area in use, uniform stress distribution, and long service life.

(3) The surface is smooth and sealed, the outside air and water are not easy to penetrate into the inside of the wire rope, and the internal lubricating oil is not easy to run off, which can prevent the corrosion of the inner steel wire.

(4) The twisting direction of the adjacent layers of steel wire is opposite, with good non-rotation (see non-rotating wire rope), large twist distance, and small structural elongation.

(5) Very poor flexibility, can not be bent on a smaller radius, the use of larger diameter rope wheel and reel, the ratio of diameter to rope diameter should generally reach 165:1, the minimum should not be less than 115:1, Therefore, the use range of such steel wire ropes is limited.

(6) Manufacturing is more complicated and costly.

Range of use

locked coil steel wire ropes is a kind of special structure steel wire rope, which has very excellent performance. In many cases, it is irreplaceable by any other materials. The locked coil steel wire ropes is mainly used in some large-scale hoisting equipment, mines, shafts and hoists, overhead ropeways and suspended suspension bridges for transporting goods and people. The places with the most applications are passenger ropeways, freight ropeways, cable cranes, roof suspension structures for large houses, bridges, and mine lifts.

Contact: AULONE

Phone: 86-15573139663

Tel: 86-15573139663

Email: admin@aulone.com

Add: Address:Kaiyuan road 36,Chunkou,Liuyang, Hunan,China. Email: info@aulone.com