Features

• Designed to have a specific unit weight

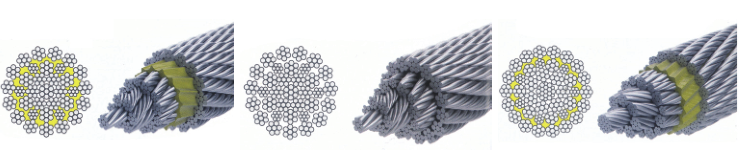

• Impregnated and coated with tough polymer,

offering superior protection against the harsh,

aggressive environment of a shaft mine

• Can be used with a swivel

• Available in ordinary (regular) lay or lang lay

The application and characteristics of the balance flat rope:

According to the growing demand for the growing mining industry, Aulone can provide the most matched mining wire rope according to the conditions of the working conditions: including a variety of dedicated structures and mutual services. By customizing and testing its superior performance and value, the wire rope provided by our company is a high -performance steel wire rope specifically for the application of the balance flat rope for friction winders.

Contact: AULONE

Phone: 86-15573139663

Tel: 86-15573139663

Email: admin@aulone.com

Add: Address:Kaiyuan road 36,Chunkou,Liuyang, Hunan,China. Email: info@aulone.com